Welcome, all! If you’ve got a chainsaw in your shed and need help measuring its bar, you’re at the right place! By the end of this article, you will have all the tools and knowledge needed to measure on how to measure chainsaw bar accurately. Buckle up as we are about to slice into the world of chainsaw bars.

1. Why Accurate Measurement Matters

Accurate measurement of the chainsaw bar and Chain is crucial because it directly affects its performance and safety. A correctly sized bar and Chain ensure efficient cutting and reduce the risk of kickback, which is a sudden and dangerous upward movement of the chainsaw when the Chain gets pinched. Knowing the correct measurements allows you to choose the perfect replacement parts for your chainsaw, avoiding unnecessary hassle and ensuring smooth operation.

2. Measuring the Chainsaw Bar Length

To measure the chainsaw bar length accurately, follow these steps:

- Remove the Bar: Start by disconnecting the spark plug to ensure the chainsaw doesn’t accidentally start. Then, remove the guide bar from the chainsaw body.

- Measure Effective Cutting Length: Measure from the tip of the guide bar to where it enters the chainsaw body. This measurement is the effective cutting length.

- Measure True Bar Length: For a precise measurement, take the bar off completely and measure its entire length, including the part that fits into the chainsaw body.

3. Understanding Chainsaw Bars

But first, let’s answer the most basic question. What exactly is a chainsaw bar? It’s that piece of metal that guides Chain around. Chainsaw bars come in various sizes, with the bar length determining the depth of cut you can make. Now, let’s dive into how to measure this bar correctly!

4. How to Measure Chainsaw Bar?

Steps for Measuring the Bar Length

To measure a chainsaw bar, follow a few simple steps.

Step 1: Measuring the Cutting Length

First, disconnect the spark plug wire for safety. Then, place the chainsaw on a flat surface. Measure from the bar’s tip to where it enters the chainsaw’s body. This gives you the cutting length.

Step 2: Finding the True Length

Next, remove the clutch cover and measure the bar from end to end. That’s the true length of the chainsaw bar. Remember that these measurements are often rounded up to the nearest even number.

The Importance of Accurate Measurements

Why is it so crucial to measure the chainsaw bar accurately? Precise measurement ensures a perfect fit when replacing the bar or Chain. Would you want to avoid ending up with an incompatible part?

5. Chainsaw Chains

Measuring the chainsaw bar is only half the battle. You also need to understand the chainsaw chain’s measurements.

Chain’s Pitch

The Chain’s pitch can be found by measuring the distance between three consecutive rivets and dividing it by two.

Chain’s Gauge

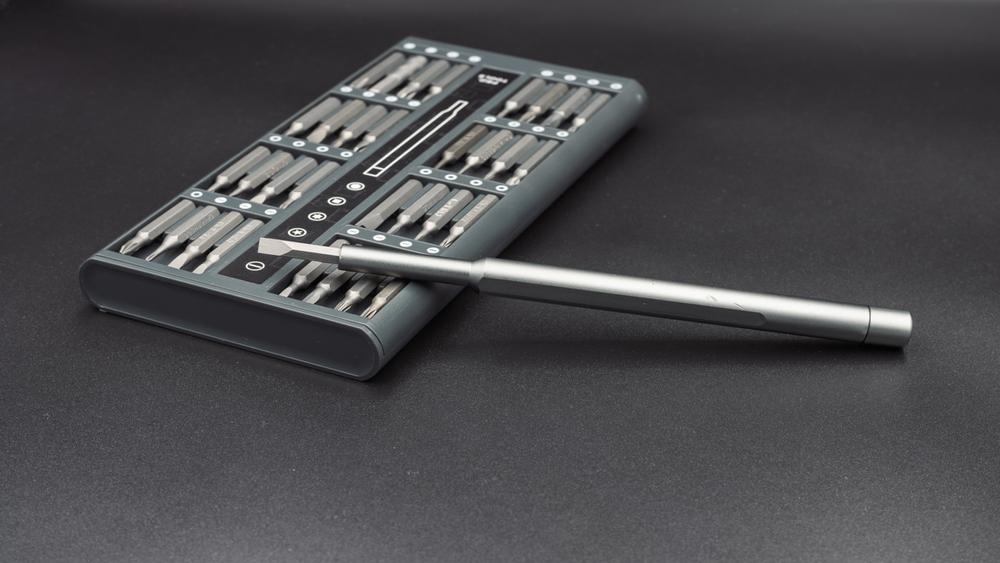

The Chain’s gauge refers to the thickness of the drive links. Use a calliper or a multi-purpose gauge to measure this.

Number of Drive Links

Count the drive links by marking one and counting along the Chain.

6. Chainsaw Sizes and Types

Chainsaw bars and chains come in various sizes and types, each suitable for different tasks.

Gas-Powered Chainsaws

Gas-powered chainsaws are perfect for medium to large trees. They offer significant cutting power, making them ideal for heavy-duty tasks.

Electric Chainsaws

Electric chainsaws are suitable for smaller trees. They’re lighter and easier to handle, making them perfect for small jobs around the house.

Battery-Operated Chainsaws

Battery-operated chainsaws are great for medium-sized trees or pruning small limbs. They offer the convenience of cordless operation, providing excellent mobility.

7. Importance of Choosing the Right Bar Size

Selecting the right bar size is essential for safe and efficient cutting. Choosing a chainsaw bar at least two inches longer than the item’s thickness is generally recommended to prevent the saw from getting stuck in the wood.

8. Tips for Safe and Efficient Cutting

- Keep the Chain Sharp: Regularly sharpen the chainsaw chain to ensure smooth cutting and reduce the risk of kickback.

- Use Proper Lubrication: Keep the chainsaw bar well-lubricated to reduce friction and prevent damage to the bar and Chain.

- Wear Safety Gear: Always wear appropriate safety gear, including a helmet, eye protection, gloves, and sturdy footwear, when operating a chainsaw.

- Mind Your Surroundings: Be aware of your surroundings and avoid cutting near obstacles, such as rocks or metal, to prevent damage to the chainsaw chain.

- Proper Chain Tension: Maintain the correct chain tension to prevent chain derailment and improve cutting efficiency.

Discover the secrets to safe and efficient chainsaw cutting! Read our article “How to Cut Straight With a Chainsaw: Mastering Precision” for expert tips. Unlock your potential today!

9. Maintenance and Care Tips

Maintaining your chainsaw bar and Chain is essential for their longevity and performance.

Checking Chain Tension

Regularly check the chain tension. An overly tight or loose chain can affect the chainsaw’s performance and safety.

Adjusting Oil Flow

Adjust the oil flow according to your chainsaw manufacturer’s instructions. Proper oiling keeps the Chain and bar lubricated, reducing wear and tear.

Regular Sharpening

Keep your chainsaw chain sharp. Regular sharpening ensures optimum performance and longevity of the Chain.

10. FAQ (Frequently Asked Questions)

What size chain for a 16 inch bar?

Choosing the correct size chain for your chainsaw is crucial for safe and efficient operation. For a 16-inch bar, the appropriate chain size would typically have 56-57 drive links if the chain’s pitch is 3/8″ or .325″. The specific number can vary based on the pitch and gauge of the chainsaw bar.

What is gauge on chainsaw bar?

The gauge on a chainsaw bar is the thickness of the drive link that fits into the bar groove. It’s typically measured in inches; standard sizes are .043″, .050″, .058″, and .063″. The gauge should match your chainsaw chain for smooth operation.

What does 72 mean on a chainsaw chain?

The number ’72’ on a chainsaw chain refers to the type of chain. It’s usually part of a larger number that can identify the chain’s pitch, gauge, and number of drive links. For instance, an ‘Oregon 72’ chain would be a 3/8″ pitch, .050″ gauge chain.

How do you read a chainsaw bar number?

To read a chainsaw bar number, locate the markings on the chainsaw bar. They usually include the length, pitch, and gauge of the bar. Understanding these specifications will help you select the correct chain.

How do you read a chainsaw size?

Chainsaw sizes are generally read by considering the bar length, which signifies the cutting capacity, and the engine size, which indicates the chainsaw’s power. Chainsaw sizes are generally described with the bar length included.

Where is chainsaw bar length measured from?

Chainsaw bar length is measured from the tip of the chain to where it enters the housing. This measurement doesn’t include the portion of the bar that’s inside the casing.

What is a normal size chainsaw?

The term “normal-size chainsaw” is relative and depends on the specific task. A chainsaw with a bar length between 14-20 inches is considered normal for homeowners and casual users.

What is the standard chainsaw chain size?

Standard chainsaw chain sizes are based on the chain’s pitch and gauge. The most common pitch sizes are 1/4″, .325″, 3/8″, and .404″. The gauge usually varies between .043″, .050″, .058″, and .063″1. Remember, the chain size depends on your chainsaw’s make and model.

11. Conclusion

In conclusion how to measure chainsaw bar, And that’s a wrap! You now know how to measure a chainsaw bar and understand its various aspects. Remember, safety comes first! Always disconnect the spark plug before you start measuring. Happy cutting, folks!