Selecting the right screws for pressure-treated decking is crucial for ensuring structural integrity and longevity of outdoor wood projects. In this Best Screws for Pressure Treated Decking article, we will explore the top five screws specifically engineered for pressure-treated decking, providing insights into their features, benefits, and suitability. Whether you’re a novice or a seasoned woodworker, understanding the best screws for pressure-treated decking will enhance the success and durability of your projects.

| Image | Product | Details | Price |

|---|---|---|---|

|

12 x 4 Inch 305 Grade Stainless Steel Deck Screws 100 Pieces | Exterior Finish: Stainless Steel Specialty: Best for Heavy-Duty Projects |

Check Price |

|

Power Pro Premium Exterior Wood Screws, 9 x 3″, 5 lb Bucket of Screws | Exterior Finish: Bronze Specialty: Best for Versatility |

Check Price |

|

Deck Plus 48412 Wood Screws #8 x 1-5/8″, Tan, 5lb Box | Exterior Finish: Bronze Specialty: Best for Beginners |

Check Price |

|

Deck Plus 48419 Wood Screws #10 x 3″, Tan, 5lb Box | Battery Description: Alkaline Specialty: Best for Outdoor Durability |

Check Price |

|

Deck Plus 48414 Wood Screws #8 x 2″, Tan, 5lb Box | Exterior Finish: Bronze Specialty: Best Overall Value |

Check Price |

Understanding Pressure-Treated Decking

Overview of Pressure-Treated Wood Properties and Characteristics

Pressure-treated wood is a popular choice for outdoor projects due to its enhanced durability and resistance to decay, rot, and insect damage. This type of wood undergoes a treatment process that involves impregnating it with preservatives, making it more resilient against outdoor elements. Key properties and characteristics of pressure-treated wood include:

Understanding these properties is crucial for selecting the appropriate screws that will ensure a secure and durable decking structure. [1] [2] [3] [4] [5] [6]

Factors to Consider When Choosing Screws

When it comes to pressure-treated decking, choosing the right screws is essential for ensuring a secure and long-lasting structure. Here are the main factors to keep in mind when selecting screws for your project:

Key Considerations for Selecting Screws for Pressure-Treated Decking

By considering these factors, you can ensure that the screws you choose are well-suited to your pressure-treated decking project, providing a secure and reliable structure for years to come.

Types of Screws for Pressure-Treated Decking

Overview of Different Screw Materials and Their Suitability

When it comes to pressure-treated decking, choosing the right screws is crucial for ensuring the structural integrity and longevity of your outdoor space. Here’s a brief overview of the main types of screws and their suitability:

By selecting screws made from these materials, you can ensure that your pressure-treated decking remains secure and stable over time, with minimal risk of rust or corrosion compromising its structural integrity.

Recommended Screws for Pressure-Treated Decking

Recommended Screw Types

When it comes to pressure-treated decking, selecting the right screws is essential for ensuring durability and structural integrity. Here are some specific screw recommendations based on decking applications:

By choosing the right screws for your pressure-treated decking, you can ensure a secure and long-lasting outdoor space that withstands the test of time and environmental factors.

Top 5 The Best Screws for Pressure Treated Decking

Deck Plus 48419 Wood Screws #10 x 3″, Tan, 5lb Box

Upgrade your construction projects with Deck Plus 48419 Wood Screws #10 x 3″ Tan. These screws feature a self-drilling point, eliminating the need for pilot holes, and coarse screw threads for a secure grip. The tan ceramic coating provides superior rust and corrosion protection, ideal for outdoor and treated lumber applications. The star drive style minimizes slippage and camout, while each box includes a free T25 star bit. Safe for use with treated lumber, Deck Plus screws ensure quality and performance for your next project.

Key Features and Benefits

Deck Plus 48412 Wood Screws #8 x 1-5/8″, Tan, 5lb Box

Upgrade your woodworking projects with Deck Plus 48412 Wood Screws #8 x 1-5/8″ Tan. Featuring a self-drilling point and coarse screw threads, they eliminate the need for pilot holes, saving time. The flat-head style ensures a seamless finish, and the tan ceramic coating offers superior rust resistance for indoor and outdoor use. With a star drive style and complimentary T25 star bit, installation is easy. Hillman Star Drive Deck Screws provide versatility, torque transfer, and superior rust protection for woodworking projects.

Key Features and Benefits

Power Pro Premium Exterior Wood Screws, 9 x 3″, 5 lb Bucket of Screws

Upgrade outdoor woodworking with Power Pro Premium Exterior Wood Screws. Built for durability, they resist corrosion with a bronze epoxy coating. The self-starting tip speeds up engagement, and the T25 star drive minimizes camout. Each 5 lb bucket contains around 417 screws. Features include a no-strip star drive, countersinking blades, and compatibility with various wood types. Ideal for decking, fencing, and framing projects.

Key Features and Benefits

#12 x 4 Inch 305 Grade Stainless Steel Deck Screws 100 Pieces

Elevate outdoor woodworking with Allen’s Trading Co. Eagle Claw Fasteners Stainless Steel Deck Screws. Made from durable 305-grade stainless steel, they resist corrosion and come in a pack of 100 pieces, ideal for decking, fencing, and general woodwork. Suitable for coastal, wet, and outdoor use, they maintain aesthetics with high corrosion resistance. Compatible with all wood types, including pressure-treated lumber. Easy installation with included T25 Torx driver. Features Type 17 point and nibs under the head for stability. A burnished finish adds a polished look. Please note, that pre-drilling may be required. Trust Allen’s Trading Co. for premium quality and performance.

Key Features and Benefits

Deck Plus 48414 Wood Screws #8 x 2″, Tan, 5lb Box

Upgrade woodworking with Deck Plus 48414 Wood Screws #8 x 2″ Tan. Engineered for precision and durability, they feature self-drilling points and coarse threads for easy installation. Flat-head style ensures a seamless finish, while tan ceramic coating provides rust protection. Star drive style minimizes slippage, and includes free T25 star bit. Safe for treated lumber, versatile for various projects. Approximately 125 screws per 5lb box. Trust Deck Plus for premium quality and performance.

Key Features and Benefits

Best Gel Stain For Fiberglass Door: Review & Guide

Fiberglass doors are a popular choice for many homeowners due to their durability, energy efficiency, and aesthetic appeal. However, over …

Read Full ArticleBest Gel Stain For Fiberglass Door: Review & Guide

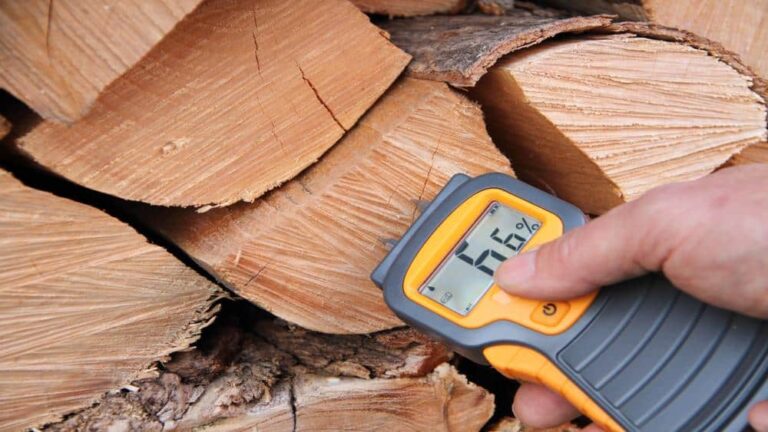

Best Wood Moisture Meter for Woodworking: Reviews

In this article, we delve into the realm of woodworking and explore the significance of selecting the Best Wood Moisture …

Read Full ArticleBest Wood Moisture Meter for Woodworking: Reviews

Best Wax for Wood Drawer Slides: Review & Guide

Selecting the best wax for wood drawer slides is paramount to ensuring the smooth functionality and longevity of your furniture …

Read Full ArticleBest Wax for Wood Drawer Slides: Review & Guide

Installation Tips for Pressure-Treated Decking

When it comes to installing screws for pressure-treated decking, following proper techniques is crucial for a successful and long-lasting project. Here are some essential tips to consider:

By adhering to these installation tips, you can ensure a professional and reliable outcome for your pressure-treated decking project.

Maintenance Tips for Pressure-Treated Decking

Tips for Maintaining Pressure-Treated Decking and Screws

Maintaining pressure-treated decking and screws is essential for prolonging the lifespan of your outdoor space. Here are some key tips to keep in mind:

By following these maintenance tips, you can ensure that your pressure-treated decking and screws remain in optimal condition for years to come.

Conclusion

In conclusion, selecting the best screws for pressure-treated decking is crucial for ensuring durability and longevity. By choosing screws with the right features such as corrosion resistance, self-drilling capabilities, and compatibility with treated lumber, you can enhance the structural integrity and aesthetics of your outdoor projects. Investing in high-quality screws not only saves time and effort during installation but also ensures a secure and reliable hold over time. Make informed decisions when choosing screws to elevate your woodworking projects and enjoy long-lasting results.