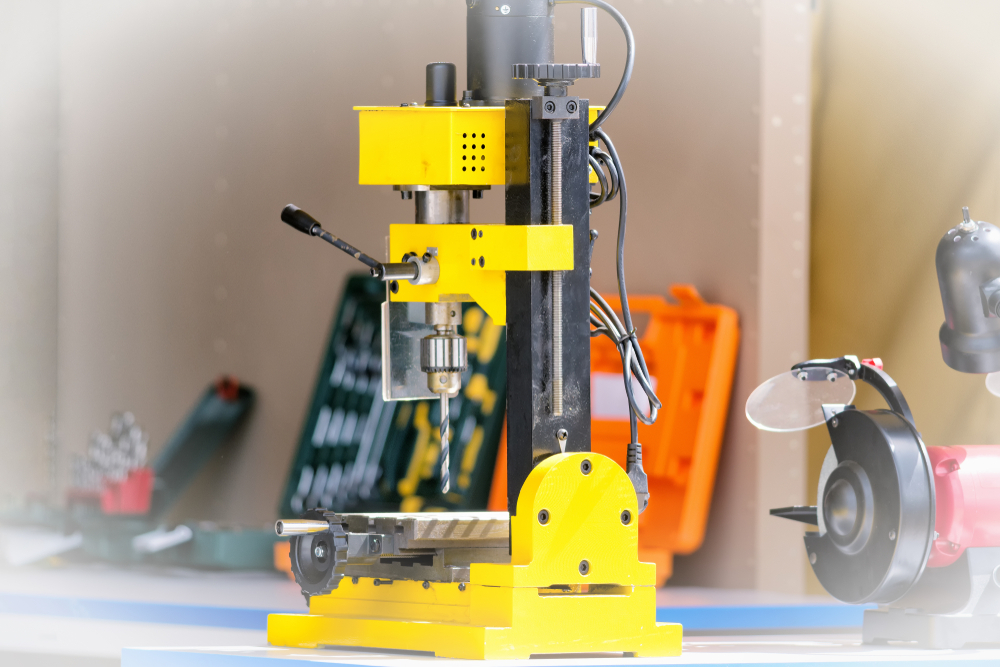

Wondering about the various applications of a drill press? This article will answer your question on “what is a drill press used for?” with more than 12 uses. A drill press is a fundamental tool that can be used for several jobs in woodworking and metal works.

It is normally used for drilling and is loved by many workers as it produces accurate work and possesses a more powerful motor. With the modifiable height, it can align the chuck and the quill making the drills to be perfectly aligned.

Still, a drill press can be fitted with different types of attachments to carry out different tasks. Here are the ways you can use a drill press.

12 Uncommon Drill Press Uses That Will Revolutionize Your DIY Projects

Drilling holes

A drill press is efficiently used by carpenters to drill accurate cut bores out of a big piece of wood. You can set the drill press to make replicate holes accurately without using a lot of energy and time. This only happens when you use the drill press correctly.

The head of the drill press together with the adjustable table provides the accurateness between the material to be drilled and the revolving drill head. Adjusting the drill press to the correct position helps you to do your work effectively and simply.

You can also adjust the rotating speed by either increasing or decreasing it to have the best speed that will allow you to steep up different sizes of the drill. When drilling holes in metals, use a tough-duty drilling press containing a more powerful motor and advanced parts that will offer consistent work for a long time.

Deburring a hole

After drilling a hole several times, you are required to de-burr it. Normally, when you drill a hole, the upper part of the hole becomes clear while the down part is left with some burrs making it chipped and uneven.

Removing the burrs is very simple using the drill press tool. You are just required to attach a de-burring tool to the drill and then exact some pressure after inserting the tool in the hole.

Reaming

In most cases, after drilling and deburring a hole becomes accurate enough. However, in case you want a more accurate one, for example, a hole with a diameter of greater than two thousand an inch, you can, therefore, use a reamer. Interference and slip fit require a reamer.

To achieve this, you should drill the hole incompletely and it should be smaller. After drilling, drive the reamer down at a steady but slow speed to achieve the desired size. The speed should be about 1/3 of the speed used to drill the same material. You should never spin a reamer in the reverse direction.

Tapping a hole

A tap is a device used to cut interior threads in a cylindrical hole. Sometimes you will be needed to cut threads in a hole. A drill press with the right tool is so far the best tool to carry out this kind of work.

This is because the task requires accuracy given that threads are extremely fragile and solid. You can perform two types of taps, the starting tap, and the plug tap.

The start tap helps you to start the thread in a certain position while the plug tap finishes the procedure by cutting the strand. To achieve correct measurements, and the configuration when tapping the hole use these tools.

Mortising

Mortises are used to cut four-sided figure-shouldered mortises. You can attach a mortising attachment to a drill press, and this will cut a very high cost. You can get a mortising attachment for every type of drill press.

Although the attachments have a different appearance from the original mortising tools, they contain three fundamental components. You need to control the drill press at the most favorable speed to succeed.

This means you will be relieved from buying and storing the large and heavy mortise. To prevent the bits to stretch and smoke. You will be required to slow down the speed of the drill.

Drill press mortise attachment is much quieter and has less nerve stretching than using a mortise. On the other hand, the attachment is a bit slower.

YouTube Video Credit: HouseImprovements

6. Countersinks

Countersinks are done to help you remove burr areas from your workplace. A drill press is used to carry out countersinks. You will require a drilling bit with a conical shape that will help you to form cone-shaped bores.

As the rotation increases you can control the drill to create the desired countersink. Many companies producing drill presses are always proud of the capability of their tools to make smooth and perfect edges. You must not be left behind as you can use your drill press to make perfect edges.

7. High-speed boring

Some materials contain different hardness and thicknesses. This causes some difficulties to handle if you are using an ordinary drill. A drill press makes this work easy particularly if you need to drill many holes without encountering alignment and depth inconsistency problems.

You just modify the speed as well as the size of the boring bit and drill holes. You will get the expected sizes of holes easily. In case you experience difficulties while positioning the bit, use a lesser diameter bit to bore in pilot strokes for future reference.

8. Sanding

The wood piece may have several curved cuts that may necessitate sanding. A spindle sander is very costly and you might not afford to get one for your workshop. This should not worry you as you can just get a barrel sander and attach it to your drill press and run it at high speed to do the sanding.

It works perfectly such that you cannot any difference between work done by a sanding machine and by a sandpaper attachment on the drill press.

9. Dusting

Messing up while doing your woodwork is very normal. However, you can avoid this if you make the right choice of a drill attachment. To dust the wood fragments, look for a dusting attachment and join it to the tip of the drill press and dust.

Some woodworkers have a preference for having a tool for every task. This may be hectic, especially for storage space and for your budget. Drill press helps you to just invest in different types of attachments, and every work will be perfectly done.

10. Screw and unscrew

You can use it to screw bolts on your workpiece just like a portable drill. You need to insert the head of a screwdriver into the drill tip. You can also use it to unscrew the bolts by rotating the screw counterclockwise.

The drill press executes this duty so fast and efficiently unlike the normal portable drill. Make sure you use the right screwdriver bit for the screw’s drive.

11. Slash drilling

Even some unique operations like slashing can be done perfectly by a drill press. Just look for slashing attachments that are readily available in the market. Attach it to your drill at the tip, and it will do the cutting. Even for a thick bush, it will slash easily.

Make sure you align the slasher blades, and the object properly then do the pilot strokes. After this lock the object tightly. If you do not have a slasher and the workplace needs to be slashed, just get a slasher attachment, which works even better and faster.

12. Counterbores

Counterbores are usually employed in case you want to make the hole bigger. If you had already made some pilot holes and you realize that you needed bigger holes you can just use your drill press.

You achieve this by boring the bores deeper or by enlarging the openings. Most professional drillers use this mechanism of counter-boring as a secret for successful work. Counterbores are used to contain bolts, socket head cap-screws, and studs.

You can also use both counterbores and countersinks. This will help you to leave out the need to create pilot strokes and start drilling immediately. This will save a lot of time, especially when doing great tasks.

Some extraordinary drill press usage that no one is talking about

- Tapering: A drill press may be used to make tapered holes, which are important for threading or fitting different-sized parts together.

- Keyway cutting: A drill press can be used to cut keyway grooves in shafts, which are used to transfer power and torque between rotating elements.

- Glass drilling: Drilling exact holes in glass: A drill press may be used to drill precise holes in glass, which can be beneficial for producing distinctive designs or adding a light source to a project.

- Bending: A drill press can be used to bend metal or plastic sheets by attaching the material to the table and applying pressure to a specified place with the drill press.

- Engraving: A drill press can be used to engrave designs or text into a range of materials such as metal, wood, and plastic using a specific engraving bit.

- Glass etching: Using a particular etching bit and a stencil, a drill press may be used to etch designs or patterns into the glass.

- Reaming: Reaming is the process of resizing and smoothing out existing holes in order to make them more exact and accurate.

Conclusion

A drill press is capable of conducting approximately all drilling-related operations more accurately than other normal drills. It is easy to operate with more power which makes it fast and efficient.

With lots of functionality, it minimizes the cost of buying so many tools for every task. This reduces the storage space as the attachments are smaller than actual machines.

In case you are a metal or woodworker, I would recommend that you invest in a drill press and all your work will be perfectly done. This unique tool is perfect even for beginners as it does not require skills to handle.

Look for the most excellent drill press that has all the features required to meet your competence and workability demands. Take good care of this wonderful tool, so it can serve you for a long. With all the uses above, I believe that the question of what is a drill press used for is well answered.